The history of the exhaust system from 1980 until today according to the vehicle's release date

The exhaust system has been used in vehicles for over 125 years. This device plays an essential role in the proper functioning of the engine. In addition to reducing pollutant emissions, it also reduces noise pollution. From petrol engines to diesel engines, LPG and E85 ethanol, the exhaust system has undergone several improvements over the years. So where does this device come from ? How did it evolve ? Do today's exhaust systems still look like the devices of the time ? Flashback !

It all starts with a simple metal pipe

The creator of the exhaust is none other than Milton Reeves, one of the early pioneers of the American automotive industry. It all began in 1896 when the American wanted to create a device to overcome engine noise and fumes. He filed a patent in 1897 and the forerunner of what would later be called the muffler was born. The improvement of this system is attributed to Eugène Houdry, a French engineer who helped create the catalytic exhaust to clean up pollution in vehicles. Around 1975, governments were looking to decrease air pollution from cars. Hence the widespread introduction of pollution control devices such as catalytic converters.

The evolution of the exhaust line, a history of technology

Decades ago, an exhaust line was a sheet metal pipe, devoid of technology, to vent gases as far away from the engine intake as possible. The reason ? The toxicity of the gases, which are a danger to passengers. This is why the exhaust systems are located high up or at the rear of the car. Nowadays, manufacturers are competing with each other to transform this simple metal pipe into a technology contributing to the management and depollution of the engine.

Over time, the roles of the exhaust line have multiplied. In addition to gas evacuation, the first task was the decrease in noise. With the addition of systems such as the muffler, engineers succeeded in attenuating the noise of the combustion engine.

The second task was pollution reduction.Since the early 2000s, more and more countries have made it mandatory the adding a catalytic converter on diesel and petrol cars. In addition, diesel exhaust lines are increasingly fitted with a DPF (diesel particulate filter) which aims to store fine particles.

For example, anti-pollution standards and research in the automotive sector have resulted in the design of more economical and cleaner cars: a car designed in 2021 emits 8 times less pollutants than a 1995 vehicle and 25 times less than a 1980 car.

The history of diesel & petrol lines

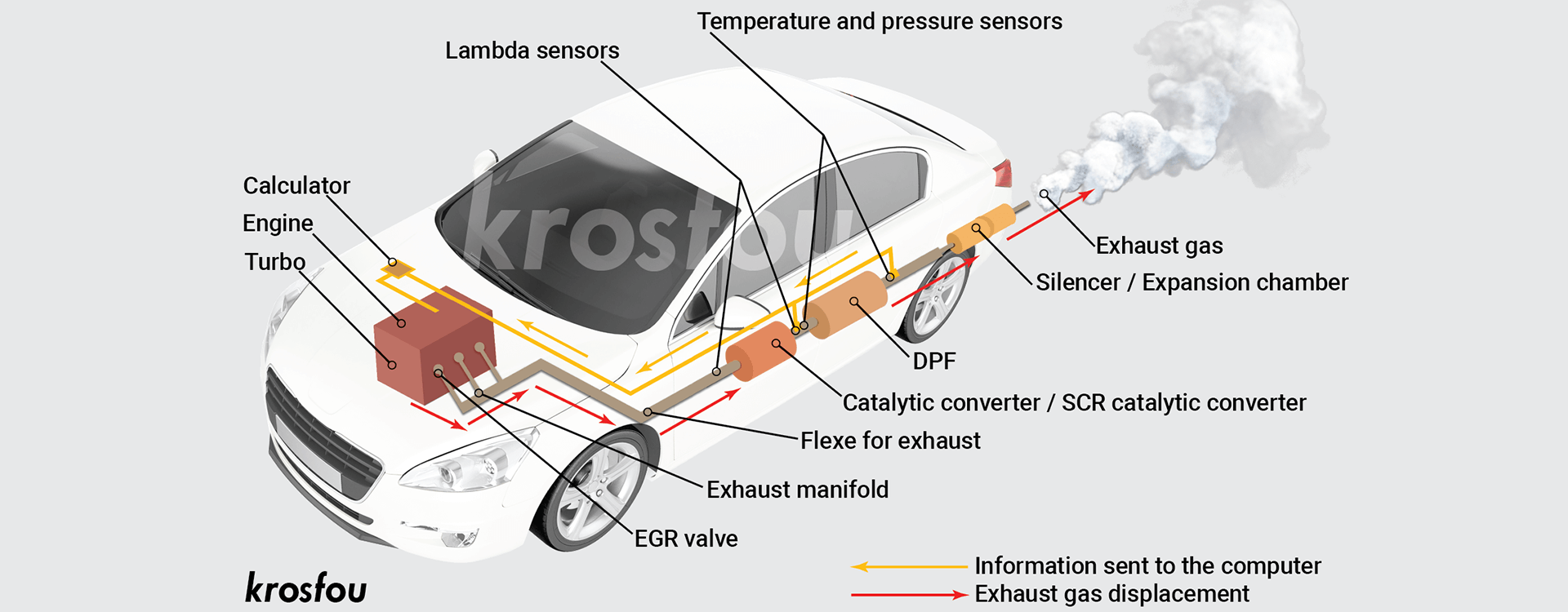

The role of an exhaust system is to direct the engine's combustion gases out of the car. Its constituent parts vary depending on the type of engine (petrol or diesel) or when the vehicle was first released.

Background on the history of the diesel exhaust line

As stated above, the components of a car's exhaust system differ depending on its year of production. In the case of a diesel engine, the following parts will be found (listed from closest to farthest from the engine):

1) The manifold : its use dates back to the launch of multi-cylinder automobiles. Located at the outlet of the cylinders, it is responsible for receiving the combustion gases. It connects the engine to the central duct of the exhaust line.

2) The EGR valve: this device helps to reduce nitrogen oxide (NOx) pollutant emissions on diesel (and petrol) engines. It began to be fitted to American diesel cars in 1970 and was later adopted in 1996 on European diesel vehicles to meet anti-pollution standards. Its opening and closing is controlled by the engine control unit via an electrical link.

Good to know: the location of this valve can change from car model to car model. However, it is often located between the exhaust manifold and the intake manifold.

3) The turbo: The history of the turbo begins around 1905. Alfred Büchi, a Swiss engineer, designed a device to increase the level of oxygen in the cylinders to improve engine performance. The operation of the turbo is relatively simple: the gases escaping from the engine turn turbines whose role is to send compressed air into the intake (hence the term turbocharger). The compressed air will be injected into the engine to increase the oxygen supply to the combustion chamber, thereby optimising power.

4) The flexe for exhaust : this is a flexible hose whose function is to connect the line to the manifold. The braid must be flexible enough to compensate for vibrations.

5) The catalytic converter : the first catalytic converters came into being at the end of the 19th century. Mandatory on diesel vehicles since 1997, catalysts convert unburnt hydrocarbons (HC) and carbon monoxide (CO) into water (H2O) and carbon dioxide (CO2), while reducing the density of diesel fuel particles. The device consists of a ceramic cavity containing precious metals (palladium, radium, caesium, alumina, etc.). The catalyst only starts the catalysis phenomenon at very high temperatures. This is why it is placed as close as possible to the engine so that it heats up quickly. It should be noted that a diesel vehicle can be fitted with a pre-catalyst (located downstream of the exhaust manifold). This device is usually fitted to newer cars.

6) The SCR catalytic converter (Selective Catalytic Reduction) : this is a catalyst model recently adopted in Europe (but which has long been fitted to American vehicles). The SCR (also called NOx catalyst) is specially designed to reduce Nox (Nitrogen Oxide) emissions by more than 90%. In fact, it is among the most efficient techniques since the implementation of the Euro 6 standard. To work, however, this device requires an additive (AdBlue) sent through an injector located on the exhaust system. Regular replenishment is therefore necessary. The origin of the SCR dates back to 1957. This device patented in the USA by Engelhard Corporation initially used ammonia as a reducing agent. But it was in the land of the rising sun, in 1978, that it was distributed on a large scale.

7) The DPF: Better known as a diesel particulate filter, this equipment collects fine particles that contain carbon. The diesel particulate filter contains silicon that filters up to 95% of polluting emissions. To reduce these fine particles, it works in two processes: trapping the particles and regeneration (eliminating the soot). The first DPF was created in the 1970s as a result of the European Union's project to reduce toxic emissions from vehicles. But it was not until the early 2000s that it began to be installed on most diesel cars thanks to PSA Peugeot Citroën. To combat air pollution, it has been mandatory since 2011 on new diesel cars.

Good to know: The catalytic converter and the DPF are usually located in the same place. But for some vehicle models, the catalytic converter is located much further upstream.

8) The expansion chamber or front silencer: It cools the gases ejected after catalysis and reduces the pressure of the gases until they reach the end of the line.

9) The exhaust pipe or rear silencer: this reduces noise pollution before the gases are expelled. It usually contains baffles and acoustic insulators such as steel, basalt or glass wool.

Background on the history of the petrol exhaust line

In contrast to its counterpart, the exhaust line of a petrol engine is simpler although some features previously dedicated to diesel are increasingly adopted.

1) The exhaust manifold

2) The EGR valve

3) Turbo

4) Flexe for exhaust

5) The catalytic converter: Petrol vehicles generally have only one catalyst (although some have a pre-catalyst).

6) The DPF: At first, DPF were only reserved for diesel cars. Nevertheless, they have become mandatory since 2015 on direct injection petrol engines with the Euro 6 standard. They are called Gasoline Particulate Filter or simply GPF.

7) The relaxation chamber

8) The silencer

How to identify line parts based on vehicle release date

Before answering this question, we must start by understanding the "Euros standards". This is a European Union regulation to limit the polluting emissions of motor vehicles. For light cars, there are 9 since 1993:

- Euro 1 (January 1993)

- Euro 2 (July 1996)

- Euro 3 (January 2001)

- Euro 4 (January 2006)

- Euro 5 (January 2011)

- Euro 6 b (September 2015)

- Euro 6c (September 2018)

- Euro 6d-TEMP (September 2019)

- Euro 6d (January 2021)

If vehicles meet the criteria imposed by the Euro standard in force (currently Euro 6d), they obtain their type approval. The introduction of the Euro standards has therefore forced manufacturers to design devices to reduce engine pollution. These include:

- The catalytic converters

- Les DPF

- Nitrogen oxide post-treatment systems (for diesel vehicles): these may be SCR (Selective Catalytic Reduction) associated with AdBlue® or a NOx trap (3-way catalytic converter + capture system).

Diesel cars

| Euro standards | The catalytic converter presence | The DPF presence | Presence of NOx filtration system (SCR or NOx capture system) |

| Euro 1 (1993) | NO (not required) | NO | NO |

| Euro 2 (1996) | YES | NO | NO |

| Euro 3 (2001) | YES | NO (not required) | NO |

| Euro 4 (2006) | YES | NO (not required) | NO |

| Euro 5 (2011) | YES | YES | NO |

| Euro 6b (2015) | YES | YES | YES |

| Euro 6c (2018) | YES | YES | YES |

| Euro 6d-TEMP (2019) | YES | YES | YES |

| Euro 6 d (2021) | YES | YES | YES |

Petrol cars

| Normes Euros | The catalytic converter presence | The DPF presence (or GPF) |

| Euro 1 (1993) | YES | NO |

| Euro 2 (1996) | YES | NO |

| Euro 3 (2001) | YES | NO |

| Euro 4 (2006) | YES | NO |

| Euro 5 (2011) | YES | NO (not required) |

| Euro 6 b (2015) | YES | YES |

| Euro 6c (2018) | YES | YES |

| Euro 6d-TEMP (2019) | YES | YES |

| Euro 6d (2021) | YES | YES |

By referring to these 2 tables, you will now be able to identify the parts that make up your line, whether it is a petrol or diesel engine. For example, an older generation diesel car will only have a catalytic converter. If it was produced after the year 2000, it will probably have a DPF and an EGR valve. Recent models are equipped with an SCR to assist the DPF. While petrol and diesel cars now share the EGR valve, the catalytic converter and the DPF, the SCR remains dedicated to diesel vehicles.

Here's an example to help you see things more clearly: you have a petrol car dating from 2006 and you notice 2 pots on the line. You tell yourself that they are a catalytic converter and a DPF. However, if we refer to the tables above, the DPF has not yet been made compulsory on 2006 vehicles. So this means that the line is equipped with 2 catalysts (1 catalyst + 1 pre-catalyst).

The exhaust lines also contain probes !

There are 3 main probes:

- The lambda sensor: its function is to analyse the composition of the gases emitted. It is thanks to this device that the computer is able to dose the air/fuel mixture. Recent cars have 2: one before the catalyst and another after.

- The DPF temperature sensor: there are 2, the first before the diesel particulate filter and the other at the rear. This device sends indications to the ECU to carry out the regeneration of the DPF and the management of the injection.

- The pressure sensor: this last sensor calculates the pressure in the duct. Its presence allows the ECU to know if the DPF is clogged.

Focus on other types of exhausts: LPG and E85 Ethanol

Concerned about nature, have you decided to adopt more "eco-friendly" cars that run on LPG or E85 ethanol ? Focus on their exhaust system !

E85 ethanol engine

Superethanol E85 is a biofuel (or rather agrofuel) made up of 75% ethanol from the cultivation of beet, corn and wheat. Its main advantage lies in its low CO2 emissions. Indeed, an E85 engine emits 50% less greenhouse gases per kilometre than a petrol engine. As for the exhaust line, you should know that it is compatible with injection petrol vehicles. If you wish to convert to E85, you do not need to make any mechanical transformation. The elements involved in the proper functioning of the system are not altered in any way.

GPL engine

>

The acronym LPG refers to 3 terms: Liquefied Petroleum Gas. It is made up of propane and butane, which makes it a fuel that can power adapted petrol engines. In fact, a vehicle equipped with an LPG engine is bi-fuelled: it has both an LPG tank and a petrol tank. It is therefore a more economical alternative to 100% petrol and diesel vehicles. The use of this fuel offers a plethora of advantages: reduced engine wear, less noise and vibration, attractive price (£0.80/litre), long range and above all a clearly favourable ecological balance. In fact, it is one of the least polluting thermal engines. Just like engines running on Ethanol E85, those running on LPG are compatible with the exhaust lines of petrol vehicles.

How is the system maintained ?

Rust is your exhaust line's worst enemy. So, check frequently for corrosion to rule out any risk of perforation. The moment rust surfaces, treat it quickly with suitable products readily available in the trade.

Good to know: Salting is very common in mountainous regions. This involves spreading salt on the road to melt the ice. However, this product can cause a lot of damage to the underbody. If your exhaust system comes into contact with salt, it can oxidise and rust. This is also the case for areas by the sea. That's why it's advisable to clean the underbody regularly.

Some parts of the line are less durable than others. The catalyst is cleaned by injecting hydrogen. Its life generally depends on the maintenance of the engine. As for the lambda sensor, it must be changed when the catalytic converter is replaced. Depending on the brand, maintenance of the DPF is recommended from 200,000 km to 500,000 km. To clean it, simply pour a suitable cleaner into the tank and drive on the motorway at high speed for a few dozen kilometres.

Parameters to watch for

Don't wait until you see a warning light on your dashboard to take action. Some symptoms to look out for in particular:

- If the engine is misfiring and you notice an increase in fuel consumption, it is quite possible that the lambda sensor is no longer able to regulate the air/fuel mixture. This symptom may also indicate deterioration of the spark plugs or filters.

- If you notice unusual rustling in the underbody, the line may be punctured. In this case, you can perform a patch without having to buy new parts.

In any case, it is best to consult a good mechanic for a checkup.

Focus on prices

The exhaust system includes several devices that vary in price. Here is an indicative table to help you.

| Line part | Price |

| Catalytic converter | Between 400 £ and 1500 £ |

| The Diesel Particulate Filter | Between 600 and 900 £ |

| Muffler | Between 120 and 400 £ |

| Lambda probe | Between 190 and 300 £ |

Before replacing anything, again, get a mechanic to look at your line and identify the source of the problem.

Where to buy parts for your exhaust system ?

On the internet, you can easily find shops specialising in the sale of exhaust parts. One of them is our company Krosfou. We stand out thanks to the quality of our catalytic converters and high-performance diesel particulate filters made of 409 stainless steel. To find the right part for your line, simply enter your vehicle number or model in our search engine. As you have discovered in this file, this is a more or less complex system, depending on the date of manufacture of your car. The only way to improve its longevity is to regularly maintain the parts that make it up.