Cordierite vs Silicon Carbide: A guide to choosing between DPF and high quality catalytic converters

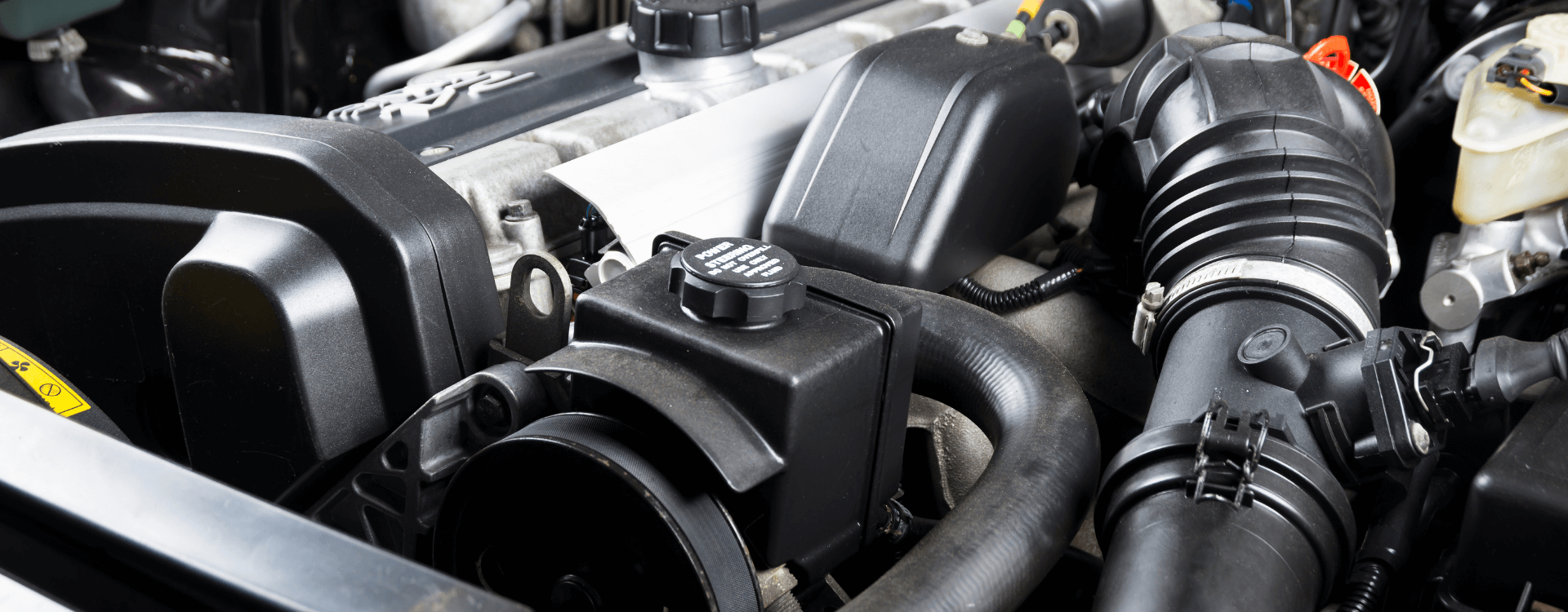

If you need to replace your car's diesel particulate filter or catalytic converter, you'll find that these anti-pollution devices are generally made from two very different ceramics. On the one hand, we have silicon carbide and on the other, cordierite. Two names that can leave you wondering, and which might lead you to opt for the more economical of the two.

However, as we shall see on this page, it is essential to make the right choice if you want your equipment to last over time ! Here's some information you need to know about choosing materials.

What's the difference between these two ceramics ?

First of all, there are several quality levels for diesel particulate filters and catalytic converters. This level of quality does not necessarily depend on price... In fact, it is above all the composition of the materials that influences quality. Some top-of-the-range equipment uses titanium or aluminium titanate..

In the anti-pollution equipment available on the market, there are two main types of material. On the one hand, we have cordierite. This is a ceramic material that provides good filtration of pollution particles and is fairly economical to produce. This makes it possible to create equipment at the best possible price.

It is actually composed of several materials: aluminium and magnesium oxides, silica and various additives. Silicon carbide, for its part, is a material that offers better filtration quality, greater thermal resistance and a much longer service life. For engines with high output, this material will be better able to optimise flows. Obviously, the production cost is a little higher, but generally speaking, the investment is worthwhile because it lasts longer..

Why is silicon carbide more expensive ?

As you will have realised, a diesel particulate filter or catalyst made from silicon carbide is more expensive to buy. But how can this be explained ?

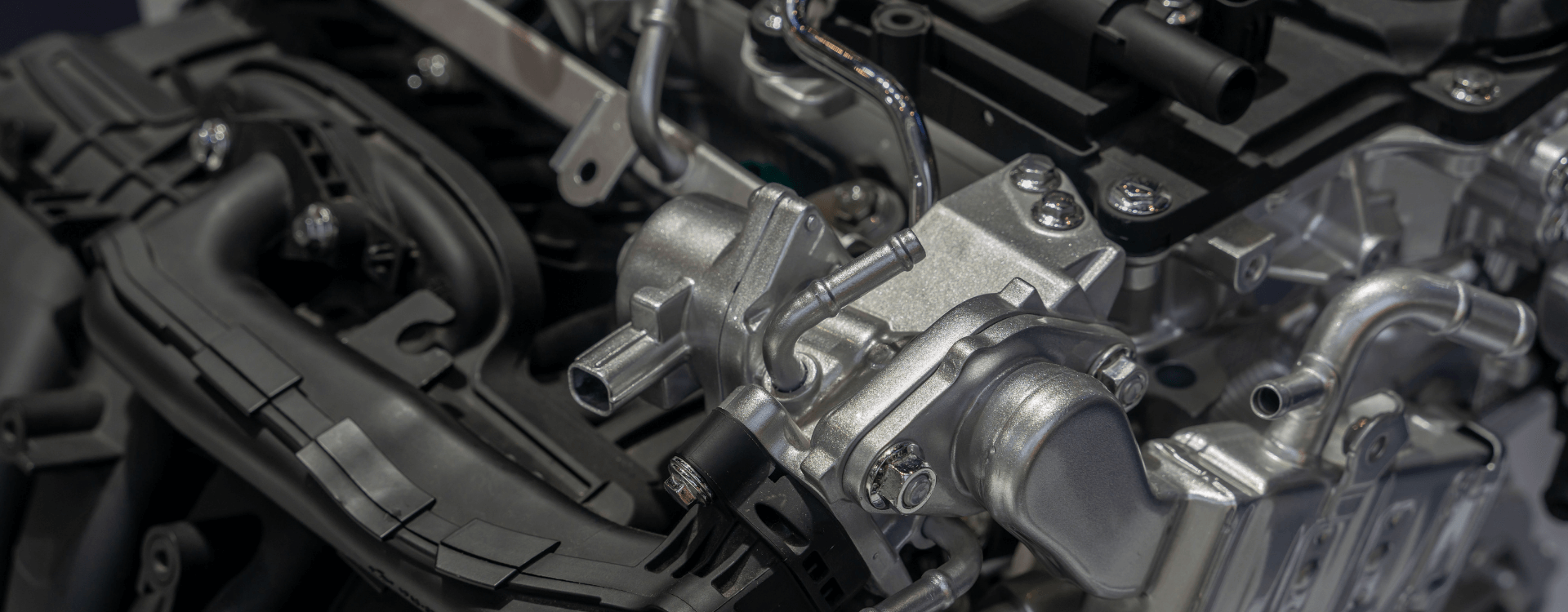

We need to look at how this material is produced. The basic material is silica sand, which is inserted into a furnace along with other chemical elements. The whole thing fuses together at a very high temperature, triggering a reaction that forms silicon carbide. The mixture then has to be cooled to solidify it and give it the desired shape. Additional finishing steps may be necessary.

All this is highly technical and requires considerable resources, particularly electricity, to reach the right melting temperature (which can exceed 1,000°C). This explains the higher cost.

Cordierite, on the other hand, involves a simpler process. The raw materials are mixed with water to form a paste. This can then be shaped into the desired form. A drying phase sets the support, which can then be used to form a new catalyst or particle filter.

Is the choice of materials really important ?

As we all know, car breakdowns always happen at the worst possible time... If you urgently need to replace your car's diesel particulate filter or catalytic converter, there's a good chance that it's going to happen when your finances aren't going so well... And even if that were the case, you'd probably want to keep your outgoings to a minimum !

Rest assured: there is no direct correlation between the price and quality of these anti-pollution devices. There are catalysts of very poor quality that are sold at full price, and vice versa. Often, it's the quality of the materials that's the problem... This can lead to premature wear of the device, resulting in higher fuel consumption and reduced power.

In all cases, it's best to avoid first-price equipment. They are often very low-end and not very durable... They are generally made from poor quality materials. Sometimes the chemical reactions are very poor because the materials used are not suitable for the job. This can slowly suffocate the engine, leading to much higher costs down the line. So you need to pay close attention to the materials used in a diesel particulate filter or catalytic converter.

As we often say, it's the internal structure of this equipment that makes an effective contribution to reducing pollution. But even more than the environmental impact, exhaust gases flow through these components. If the flows are not properly managed, you run the risk of very rapid clogging, or even suffocation. You might think that the catalytic converters sold in dealerships are the absolute benchmark, but that's not always the case... So it's important to make sure that your new catalytic converter is well made, with a good quality structure. Believe me: it can save you costly repairs in the medium term.

Similarly, it's best if the body of the catalytic converter is made of stainless steel. This prevents rust, which can quickly weaken the device. The various roughnesses in the road can damage the coating. If it's made of steel, this can lead to rust, initially on the surface, which can then lead to perforation. This can lead to premature replacement of the equipment.

Price should not be the main purchase criterion

It's not difficult to find catalytic converters or diesel particulate filters at very low prices. But these are rarely good buys. Above all, you run the risk of regretting it in the medium term.

However, the most expensive equipment is not necessarily the best. Some equipment manufacturers, some of them very reputable and recognised, have no hesitation in rounding off their margins by opting for poor quality materials.

So before you buy an anti-pollution device, we recommend that you take the time to look at the materials used. Go for the best value for money, and don't be taken in by over-selling, which often tries to compensate for poor quality.

When it comes to choosing between silicon carbide and cordierite, the first thing to consider is your use. If you drive a lot, mainly on the motorway, the first of the two will be more likely to circulate the gases correctly.

The way in which these two ceramics are manufactured goes a long way towards explaining the difference in price. The first is based on the fusion of raw materials, while the second is more of a mixture. Cordierite is not a bad choice, but its performance is slightly less than that of silicon carbide.

Finally, it's important to choose a catalytic converter or diesel particulate filter, as these devices play an active part in reducing polluting emissions from cars. As well as allowing you to consume a little less, good quality devices can significantly reduce pollutant emissions. It's good for the planet, but it's also good for your savings, as it reduces the risk of having to undergo a second inspection at the next roadworthiness test.

Image source:

Karolina Osinska / Author: fxquadro / Licence ID: CEYHRUZB8N - elements.envato.com